TRI Pack Films

- LINE 3 Ventilation AC Showering Refurbishment.

- Machining, Piping, Installation and all kind of fabrication works.

- Installation of Hydraulic Jack on Cast for Line 3 & Line 4.

- Installation of Web Inspection System provided by Dr.Schnek.

- Installation of Metallizer K5000 Expert.

- Installation of Prime Slitter Silver Line of KAMPF Germany.

- Installation of Heat Transfer Wall at Mitsubishi Line 3.

Zaman Textile Mills

- Fabrication and installation of Yarn Dying structure of Loris Bellini.

- Fabrication and installation of Yarn Dying Crane 10 ton.

- Complete Ducting Of Dying Machine.

- Fresh Air Ducting.

- Fabrication of Utility Bridge (200 Meters) For Steam/ Oil / Air / RO Water Lines.

- Installation Terbine Chimney.

- Installation of AHU (20/8 Ton) Block with Ducting and Installation in Utility.

PIBT

- Replacement of Hopper Plate in Hardox 400.

- Refurbishment of Coal Loading and Off Loading of Grab.

- All kind of machining and Fabrication works.

DP World

Fabrication of 1.5MW diesel engine. All kinds of machining works. (1996- Present).

AGP Pharma

AHUS installation, chiller Installation, Gas engine and Chiller Piping.

Pharm Evo

AHUS installation, chiller Installation, Gas engine and Chiller Piping.

Indus Dolphin Port Qasim

Dragger Annual Maintenance project (2018-2021).

Orient Textile

Donier Loom Leftoff Housing and worm gear.

Bari Textile

5MW Generator installation complete with Cooling Towers, Chillers and Ventilation.

Nagaria Textile

Piping, Fabrication, Ducting and Project Management.

Lucky Textile Mills

- Manufactured BRUCKNER Stenter Burner Tube

- Basically, These are Stenter burner tubes.

- Made from STAINLESS STEEL 310 USA sheet.

- These tubes can bear temperatures up to 1200’C.

- These tubes are used as a burner to burn the fabric and stretched it up to its required width.

- We are manufacturing these tubes as per standard.

- STEEL 310 USA sheet is our stock item.

Repair and Maintenance Contractor for JNP and NLC (1992- 2000)

JNP, a UK based company, who constructed superhighway and Karachi-Khuzdar Highway. We were their sole contractor for the repairing and maintenance of all kinds of construction machinery. We used to repair and fabricate new parts of the shovel, Road roller, dumpers, cranes and excavators. We performed the same job for NLC, Pakistan, who have developed DHA Karachi. In a nut shell, we have tremendous experience in repairing and development of all kinds of construction machinery.

Mechanical Contractor of DP World (QICT), Port Qasim

We are with QICT as their mechanical contractor and supplier since its inception. To date, we have performed copious jobs for all the terminal equipment including STS (Sea to Shore Crane), QC (Quay Crane), RTG (Rubber Tired Gantry Carnes), RS (Reach Stacker), EH (Empty Handler), and Heavy Duty Lifters. We have exceptional skills, understanding, knowledge, and experience in the development and repair of all kinds of parts related to the above-mentioned equipment. Some of our recent jobs performed for QICT as presented as follow.

Installation of the platform at STS for 1MW Engine

We have fabricated the platform for the installation of a 1MW engine. Our design is based on engineering code and conduct for marine engineering. We have installed their platform. In record-breaking 2 days to reduce the downtime.

PIBT

Replacing of grab scoop plants

At PIBT terminal, we have performed the replacement of grab plates as per OEM requirements. We have developed a WPS(work procedure schedule) to perform their tasks. We used Argon 51 code 70 sheets for the grab wrecked sheets dismantle through plasma cutting and new sheets welded in CO2 (MIG Welding).

FAP Terminal (storage warehome sheet replacement)

PEB structure, slope 37 sheets replaced. Old dismantle new Awzine sheet installed.

Part Modelling and Design in CATIA V5

We are the only Mechanical Contractors in Pakistan, who have the competency to design and simulate parts of any machinery in CATIA V5 (Software). Our General Manager Operations, MR. Khawaja Abdul Rehman is UK graduated Mechanical Engineer (BE), Oil and Gas Engineer (MSc). He has the competency to generate technical drawing, develop parts and assembly modeling in CATIA V5.

Marine, Mechanical and Fabrication

We have done numerous jobs in the field of marine, mechanical and fabrication for Multi-national industries. Some of our major fabrication projects are:

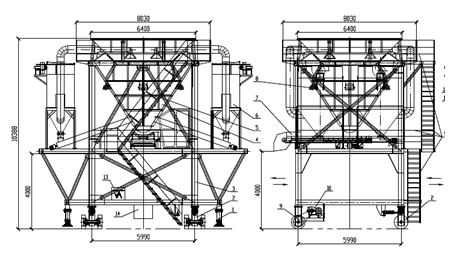

Wheat Extraction Evacuators (1994)

Along with the hoppers, we have also fabricated with wheat extraction evacuators for Gokal Shipping Corporation, Mega Equipment, Orient Trading Pakistan, and International Shipping. These Evacuators have the tendency to process 90 TON PER HOUR.

Wheat Extraction Hoppers with Conveyor Trolleys and Pump (1994)

We are the first Mechanical Contractor in Pakistan, who have erected wheat extraction hoppers for Gokal Shipping Corporation, Mega Equipment, Orient Trading Pakistan, and International Shipping. We have developed 4 Bottles Hopper, which have the tendency to produce wheat from four sides at the same time along with the conveyor trolleys.

Repairing and Rebuilding of Sea Cleaning Grabs (1998)

We have repaired and rebuild the pins bushes of grabs for OFFSHORE PIPELINE INSTALLATION (OPI, UK). The main task was to dismantle the worn plates and fixed the new ones with greater thickness. We have also repaired the cargo handling grabs for Gokal Shipping Corporation by replacing bearings, pins bushes, mounting plates, and main motors.

Heavy Engineering:

Mechanical Contractor for Denim and Textile Industry:

Mekotex Group of Industries

We have been working with Mekotex group of industries since 1991. We provide all kind of mechanical and fabrication services to all of their companies, which include Mekotex Pvt. Ltd., Arif Industries, Zamil Textile, Aquagen Pvt. Ltd. And Kam International. Some of our major jobs for Mekotex are:

- Upgradation of 24 Rope dying to 28 Rope

- Upgradation of 12 Rope Dying to 16 Rope

- Erection of Zamil Textile

- Erection of Picanol Summum Shed (120 Looms)

- Repair and maintenance of all the parts of weaving, spinning, warping, rope dying, jacquard and printing equipments.

- Repair and maintenance of power houses of Aquagen Pvt. Ltd.

Orient Textile Mills

We are the sole mechanical servicer provider to Orient Textile till date. We developed parts for all kind of Dornier (Swiss) looms as in Lett of housing and Worm gear in S.G iron. We are also specialized in all kind of gear fabrication and we have vast quantity of gear fabrication cutters, of all modulus and DP.

Other than Mekotex and Orient, we have conducted the erection of Zaman Textile in 2013. We are also specializing in cloth roll, dying roll, sizing roll, mercerizing roll and weaving beam barrels. To put it briefly, we provide all the kind mechanical and fabrication services to textile and denim industries.

Tri-Pack Films, Port Qasim

Tri-Pack Films is another example of our exceptional erection. Other than its erection, we are solely responsible for all the mechanical repair and maintenance. We develop all kind of gears for CPP and BOP lines, rubberized and chrome rolls for their films, of different sizes and materials, high pressure boiler pumps for CPP lines. We also provide overnight services to Tri-Pack in case of emergency shutdown due to mechanical fault. Moreover, we are also responsible for power house repair and maintenance.